Traktech opens its showroom with machinery for empty bottles handling

Traktech, specialists in handling empty containers at the beginning of the production line, has recently opened a showroom in their factory in Terrassa, Barcelona, where customers who are interested, have a space to try their containers with different types of machinery such as positioning, rinsing or air conveyors, among others.

This corresponds to our commitment to serving customers, where we have prepared a unique space as a Showroom to present and demonstrate our experience and the advantages of our machines for handling containers.

The permanent showroom occupies 65 square meters and it has a screen for videos as well as an extensive collection of samples of different container formats and sizes, especially bottles, for which the machines have been made.

In the customer area, you will have the opportunity to test your glass, plastic, or metallic bottles with the machinery on display.

What machines will be displayed in Traktech’s Showroom?

Traktech has displayed the most interesting and popular equipment for customers, thanks to the advantages and they its offer for production lines.

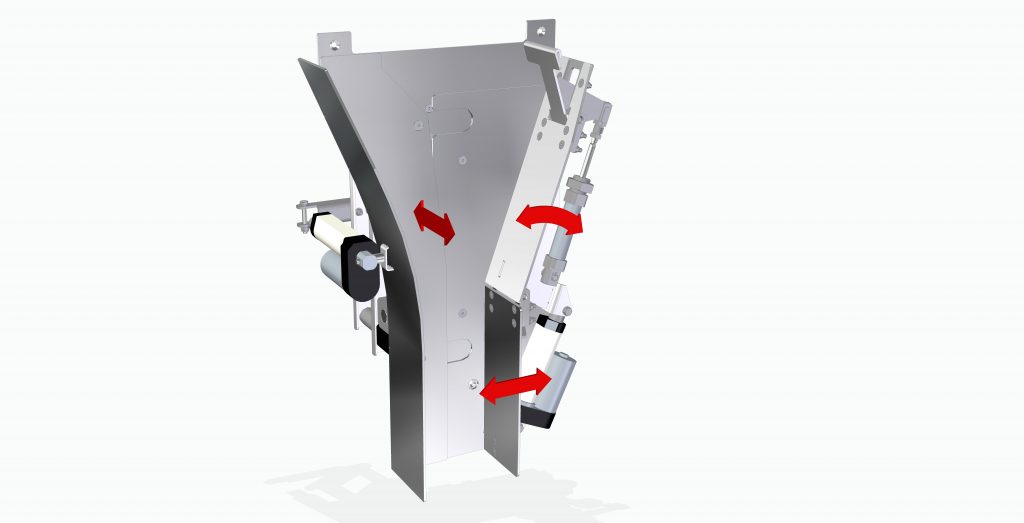

AAF funnel simulator

Our ROTRAK (AAF) Rotary Unscrambler with automatic changeover format is the most popular machine on the market by far, the funnel of the automatic format changeover being the star element.

For this reason, an AAF funnel simulator has been included in the showroom, equipped with unscrambler technology, for potential container positioning tests, which will be able to carry out the three basic movements of an automatic funnel:

The three funnel movements

Rotary rinser R-10

In Traktech’s Showroom, visitors can also see the Rotary Rinser model R-10, a compact solution for cleaning the inside of containers, of which we can highlight:

- Tipping system: The system of tumbling the containers in our Rinser R is done by means of a vertical carousel attached to the side of the conveyor.

- Cleaning system: The cleaning system is by blowing with compressed air, filtered and optionally with ionized air. The machine has a collection drawer.

- Format change: The change of format consists of exchanging the segments for each different form of container and changing the plastic guide that diverts the containers to the carousel. Both changes are made without tools.

- Type of container: This type of machine is valid for PET, glass or metallic containers of cylindrical or square shape and at maximum speeds of up to 4000 BPH.

Air conveyor for containers and Twistrinser

Other machines that the customers can see in Traktech Showroom are the Air Conveyor for moving PET bottles, and the Twistrinser.

Most important features:

The tipping system: The containers rotate in a spiral motion with regard to the centre of the air conveyor. The bottles DO NOT leave the neck guide, so there are no problems for transfer between machines.

Cleaning system: Once the containers are inverted, they are subject to a continuous stream of blown ionized air (filter H14) and suction of particles using Ionrinse™.

Advantages:

- No water expense

- No chemical residue

- No compressed air costs

- Minimum maintenance costs

- Totally integrated control system

- Easy integration into existing air conveyors

- A compact and autonomous system

Traktech intends to enlarge its exhibition of container handling machines in the near future, including a ROTRAK AAF rotating unscrambler model 1100/8 with automatic format changing.

If you would like to visit our showroom and see the machines on display, please fill in our contact form.