CHP conveyor lubrication

![]()

Description

Conveyor lubrication is essential for the circulation of containers in a production line to be fluid and continuous, as well as to guarantee the correct operation of production and ensure maximum productivity in the production line.

With these aims in mind, Trakteck uses CHP conveyor lubrication. CHP is a company that has solely and exclusively been dedicated to dry lubrication systems for conveyors since 1997.

Traktech is an official distributor of CHP’s dry lubrication system.

Lubricant presentation

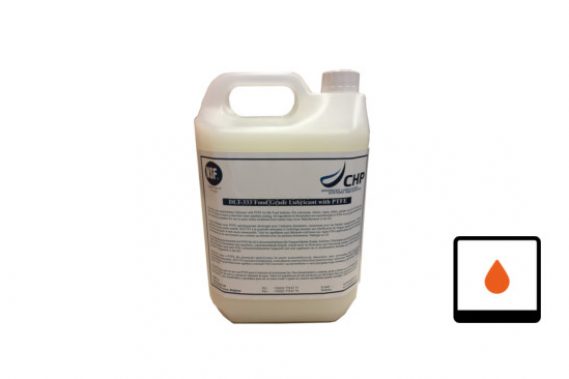

The lubricant can be supplied in 5-litre containers or a 420 ml spray. We have a permanent stock of both. Minimum orders for each are:

- 1 box containing two 5-litre containers.

- 1 box containing six 420 ml sprays.

1 package with two 5 L drums

1 package with 6 cans of 420ml

CHP evolution and its lubrication system for conveyors

Began with cardboard container lines.

System for PET lines developed.

First prototype for air conveyors developed.

First can line installed.

First “all in one”

(lubrication + CIP) developed.

Siemens S-7 control introduced.

Traktech applies CHP micro-lubrication to

Conveyors and accumulation table of filling lines

The system lubricates the contact between the guides and the conveyor chains, and between the chain and the product being moved. No brushes or sprays are used, just the principle of direct contact.

Air

conveyors

We lubricate the surface between the bottle ring and the neck guide. A worldwide patent protects this system that can only be installed by CHP. Lubricating the air conveyors, we can practically eliminate all line stoppages caused by this type of conveyor and reduce the consumption of the fans.

Spot lubrication in different lubrication points

It is also possible to lubricate parts of machines such as transmission chains, side-grips, entry augers, etc. More than 1000 lines installed all over the world use this lubrication system for conveyor belts, for renowned clients such as Coca-Cola, Nestlé, Danone, Friesland, and many more.

Sidel and Tetrapak have approved CHP’s dry lubrication system

Types of lubrication for conveyors

There are currently 4 different systems to lubricate conveyors on the market:

Wet lubrication

Based on water or chemical products.

Semi-dry lubrication

Similar to wet, but more concentrated.

Dry lubrication

Oil-based, silicone or Teflon lubricants in a maximum concentration of 1%.

CHP dry micro-lubrication

The lubricant has a totally stable Teflon concentration of up to 6% (the components do not separate) and the global system (lubricant, control and injection system) guarantees very low consumption of lubricant.

How does conveyor lubrication work?

The conveyor lubrication system is a closed circuit from the central units, where injectors for each conveyor are inserted along the production line.

The lubrication system doses one or two drops to each conveyor at a preestablished frequency, in such a manner that a regular microscopic layer is attained along the entire length of contact between the product/chain and guides/chain.

The lubricant

DLT-333® is specially designed as a lubricant apt for food and based on a stable dispersion of fine PTFE particles in pharmaceutical grade white oil. The size of the particles and dispersion method are optimized to ensure a high level of lubrication and chemical stability, avoiding PTFE precipitation.

The lubricant has very high adhesive and water-repellent properties, making it highly appropriate for wet environments. All the components are FDA/NSF-H1 approved.

For further information about the dry lubrication system for conveyors or any other product of ours, please contact us though the following form.