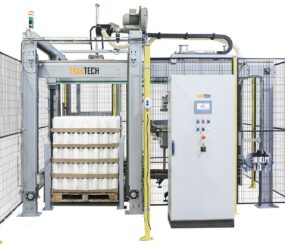

Depalletizers for glass, plastic, and can bottles

Description

Traktech are specialists in handling empty containers such as jars and bottles made of plastic, glass and tins. Thanks to our skill and experience designing and manufacturing machines, we can offer different versions of depalletizers to position containers on the packaging lines, adapting our client’s needs.

Depalletizer solutions by TRAKTECH comprise from simple pallet elevators with manual unloading of each stage, to more complex totally automated systems managing full and empty pallets.

The depalletizers designed by Traktech are able to make format changes without any worker intervention.

Product Sheet

Download Bottle Depalletizer product sheetThe most profitable depalletizer, fully automated

Based on a simple depalletizer, Traktech can develop more automatic depalletizers, also incorporating more functionality:

- Automatic container unloading system, by pushing or vacuum.

- Possibility to configure container unloading in bulk or by rows.

- Automatic system for managing layer separators, incorporating a storage deposit.

- Automatic system for removal and storage of empty pallets.

- The depalletizer system can include a station for accumulation of full pallets, to increase the autonomy of the system.

- Possibility to automate format change, without the need for worker intervention.

Traktech’s technical staff and engineers can configure out the most profitable version of the depalletizer system for their company.

Customised depalletizers

Using Traktech’s depalletizers, containers can be delivered into the Filling line in different ways, according to the unloading system used:

- If the containers are unloaded by row, the depalletizer can deliver them through vacuum conveyor.

- If the container unloading process is in bulk or using a vacuum head, the depalletizer can deliver them by an in-liner conveyor.

All these solutions are developed using equipment and technology developed by Traktech, therefore, the possibilities for customizing are infinite.

Simple and economic depalletizers

Traktech can offer simple and economic depalletizers solutions for producers, comprising a pallet elevator, protected by a metal cage, where every layer of containers is unloaded manually, by a pusher mechanism.

Video

Depalletizers with air rinsing

Traktech, to complement the depalletizers, offers the option of incorporating an air rinser in the conveyor that takes the containers down to the height of the filler.

This solution of depalletizers with air rinsing provides important competitive advantages:

- Reduces the space occupied by the machine; as a result, it increases the productivity per square metre.

- Reduces the cost and the payback period of the investment thanks to the possibility of sharing electronic components between both pieces of equipment.

- Reduces incidents and increases productivity of the line, due to the elimination of an interface between equipment made by different manufacturers.

Using Traktech’s depalletizers to manage empty containers contributes to increased efficiency of the companies in their filling lines, whatever container is used.

Depalletizers can be

By pushing and unloading either bulk or in line.

Simple version with pallet elevator and manual layer unloading.

Configurable version for greater autonomy.

Empty pallet storage.

Automatic system for removing and storing separators.

PLC format change.

For further information about the Depalletizers or any of our products, please contact us, using the following form.